Understanding the Economics: Cocoa Processing Plant Cost Analysis

Table of Contents

Introduction:

Cocoa, often referred to as the “food of the gods,” is a key ingredient in one of the world’s most beloved treats: chocolate. Behind every delicious bar of chocolate lies a complex process of cocoa bean processing, which involves cocoa processing plants.

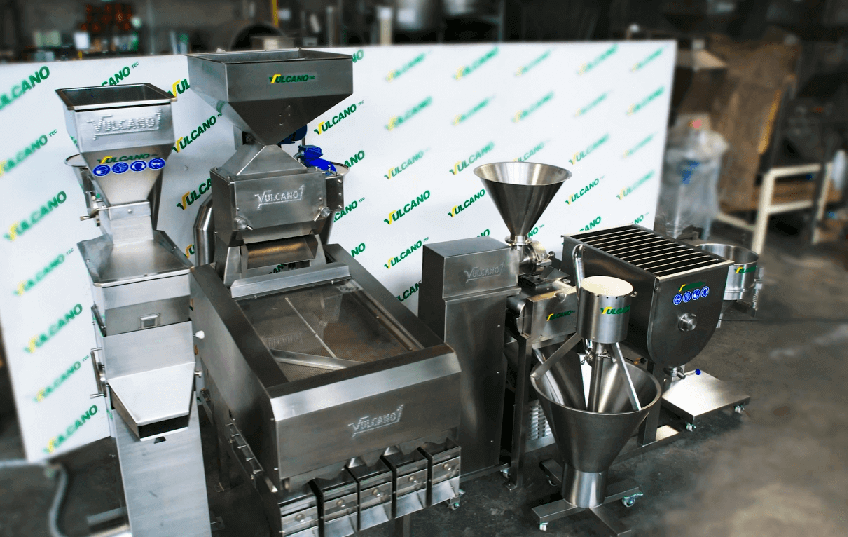

These plants are essential for transforming raw cocoa beans into the delectable chocolates we enjoy. For manufacturers like Vulcanotec, understanding the economics of cocoa processing plant costs is crucial for efficient and sustainable production

The Complex Journey from Bean to Bar:

Before delving into the economics, let’s take a brief look at the journey cocoa beans undergo in a processing plant. Cocoa processing involves several crucial steps, including:

Fermentation: Freshly harvested cocoa beans are fermented to develop their unique flavor profile.

Drying: Fermented beans are dried to reduce moisture content and prepare them for further processing.

Roasting: After fermentation and drying, the cocoa beans are roasted to develop the chocolate flavor we all love. Vulcanotec’s state-of-the-art roasting machinery ensures precise temperature control, optimizing the flavor development process.

Cracking and Winnowing: Following roasting, the outer shell is removed from the beans, leaving behind cocoa nibs. Vulcanotec’s equipment for this stage ensures efficient and consistent results.

Grinding: The cocoa nibs are ground into a thick, chocolatey paste known as cocoa liquor. Vulcanotec’s grinding machinery is designed to achieve the desired fineness and consistency.

Conching: The chocolate liquor is conche to achieve the desired texture and taste in our Conche Machine you will create the best flavor.

Molding and Cooling: The final chocolate product is molded into bars or other shapes and cooled.

Economic Considerations:

Now, let’s shift our focus to the economics of cocoa processing plants. For companies like Vulcanotec, which specialize in manufacturing cocoa and chocolate machinery, these considerations are paramount:

Initial Investment: Setting up a cocoa processing plant requires a significant initial investment in machinery, infrastructure, and skilled labor. Vulcanotec plays a vital role in supplying the necessary machinery for this purpose.

Operational Costs: Maintaining and operating cocoa processing machinery, energy costs, labor, and raw material procurement are ongoing expenses that influence the plant’s economics.

Efficiency: Efficient machinery can reduce processing time and energy consumption, thereby lowering operational costs. Vulcanotec’s high-quality machinery can contribute to improved efficiency.

Quality Control: Maintaining consistent product quality is crucial for consumer satisfaction and brand reputation. High-quality processing equipment from Vulcanotec ensures precise control over the processing parameters.

Market Demand: Understanding market demand and trends is vital for planning production schedules and optimizing plant operations.

Sustainability: In today’s world, sustainable practices are not just environmentally responsible but also economically viable. Sustainable cocoa sourcing and processing can attract eco-conscious consumers.

Conclusion:

Cocoa processing plant cost analysis is a multifaceted endeavor, with numerous factors influencing the economics. Manufacturers like Vulcanotec play a pivotal role in providing state-of-the-art machinery that can enhance efficiency, improve product quality, and contribute to cost savings in the long run.

As the cocoa and chocolate industry continues to evolve, a keen understanding of these economic considerations is essential for businesses aiming to thrive in this delectable market.